Maretti Lighting stands out in the lighting industry by offering custom solutions, both on a project basis and within our product lines. Thanks to our extensive workshop, we are able to produce nearly everything in-house, ensuring maximum flexibility and creativity. Our design and product development departments create the most refined designs for our regular collection, such as the beautiful Glass Jewel pendant light. In addition, we realize unique custom specials for large-scale projects, such as the impressive lighting installations at Van der Valk Heerlen. With our expertise and craftsmanship, we create lighting that is both functionally and artistically distinctive.

Van prototype tot productie

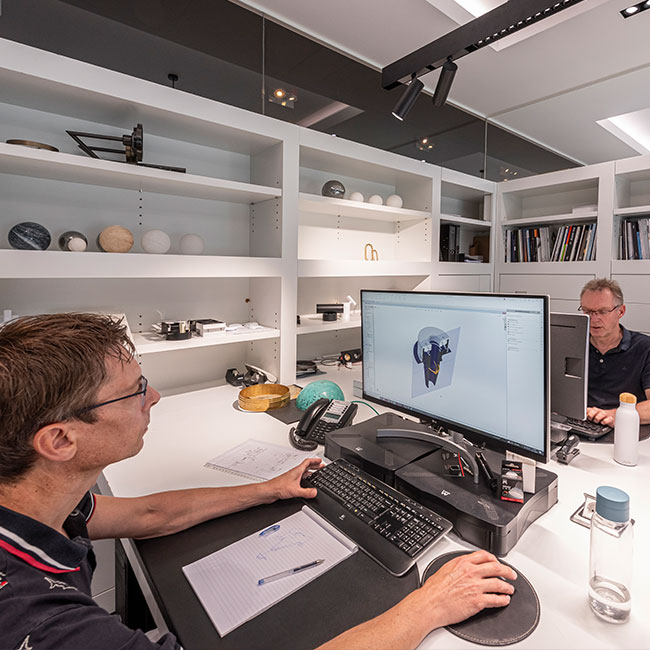

After an initial conversation with the client, the actual design work begins at the "drawing board" in the design studio, where our 3D printer makes those designs immediately visible and tangible for the client. Creating a prototype makes the client's idea visible and tangible, allowing for constructive discussions based on that prototype. Any adjustments or modifications can already be implemented at this early stage, ensuring that the final result meets the client's expectations perfectly.

From idea to lamp all under one roof.

Our collaborations with interior designers and architects range from lighting their projects to bringing their ideas in lighting to life. Whatever they conceive, our team can create. The lines of communication between our sales, design, and production departments are so short that we can quickly communicate with one another. This ensures that the client's wishes are clearly understood across the various divisions within the design process, greatly benefiting the production process.

From Dream-Queen to Laser-King

After client approval, the design is sent to our in-house factory, where our skilled employees take on the new challenge. They have access to such advanced machinery that they can work with virtually all conceivable materials, such as bronze, glass, metal, and stainless steel. This enables them to shape any design: bending glass, welding, soldering, sawing, drilling, and polishing. We even have a glass kiln. Our production capabilities are therefore unlimited. Where something seems impossible, we see the challenge!

Creating high-quality, custom designs to enrich your project with exceptional craftsmanship.

From sales to delivery, customization is our strength.

We take providing custom solutions very seriously in all the products and services we offer. What seems impossible to others is viewed as a challenge by our team. We focus on solutions and utilize the latest technological possibilities. Our production staff is driven and well-trained, regularly attending refresher courses to stay updated on new developments and manufacturing processes. We also apply technological innovations directly in all our projects. Thanks to the craftsmanship of our entire team, we can deliver precisely the customization that the client desires.

The latest technological innovations

The research and development department focuses on the latest technological innovations, ensuring that our fixtures and products lead the industry. Our highly qualified professionals provide training in our factories worldwide, conduct on-site quality inspections, and directly integrate the latest developments and techniques into our fixtures. This extensive department is equipped with various testing equipment for light measurements, including checks on dimming quality, to ensure that our products meet the highest standards for performance and reliability.

The research and development department is dedicated to exploring the latest technological advancements, ensuring that our fixtures and products lead the industry. Our expert team conducts rigorous quality control and integrates the latest techniques into our fixtures to ensure that each product achieves the highest levels of performance and reliability. By continuously pushing the boundaries of innovation, we deliver exceptional lighting solutions that set new standards in design and functionality.

We strive for innovation, quality, and performance.

Maretti Lighting warehouse

At Maretti Lighting, our 3,220 m² warehouse is the heart of our operations. This central hub allows us to deliver many products directly from stock, guaranteeing fast delivery and reflecting our commitment to customer satisfaction and efficient service.

Our modern logistics strategy ensures smooth order processing, handling, and information provision, all aimed at exceeding customer expectations. Service is our top priority, and we demonstrate this through expert installation, timely deliveries, and exceptional after-sales support. Additionally, our dedicated maintenance and troubleshooting service provides ongoing reliability and peace of mind for our customers, even after the project is completed.

Support and advice

Our experts provide on-site support and advice, ensuring that every detail is executed according to our high-quality standards and that the final installation perfectly aligns with the design and the client’s wishes.

Maretti Lighting custom projects